About Tactile Knife Co.

Tactile Knife Company has a massive leg up from most new knife companies because we already have a team of talented craftspeople, a large shop for amazing new equipment, and more turning capacity than basically any other knife company, period, thanks to our years of experience making quality machined pens (see Tactile Turn).

Many of the biggest knife companies make most of what they sell, but quite a few outsource it to the cheapest options around the world. Almost none actually make their own screws and pivots. Our intention is to make everything we possibly can in our shop, only buying raw materials and ceramic ball bearings from two outside companies because they have equipment that just doesn’t make sense at our scale.

Hopefully in the next year or two we'll be able to bring that in house as well.

The more a company has to rely on outside sources, the less control they have over the quality and timeline. When we started this project it was looking like it was going to take 8-12 weeks to go from raw blade stock to a finished blade. Now we have it down to about two weeks.

This is important because we can tell our customers on the wait list reliable and consistent timeline estimations for when they'll be able to purchase a knife. Will and the team knew when starting this venture that they had a serious task at hand and the goal from the start was to always try to meet customer demand.

Committed to the craft

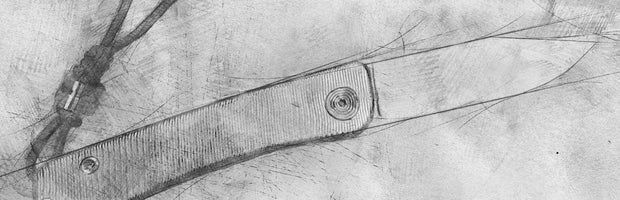

For months we have been toiling over design and the process to make them painstakingly looking at every aspect. For example, there are lots of ways to make a blade. The method that has been common for centuries is to find a piece of steel and heat it in a forge to make it into the rough shape of the blade, quench it, and grind off excess material. It’s an amazing process when done by a skilled craftsperson, but hard to get exacting precision needed in a quality folding knife.

There are several ways to cut steel for production knives. Plasma torches are an option, but almost never used. Waterjet and lasers are even more accurate and both are fairly common in large and small companies. The most accurate method to cut flat material, however, is to do it with a Wire Electrical Discharge Machine.

Waterjet and lasers can be accurate to 0.001-0.005”. The table on our EDM is guaranteed to hold 0.0001” for ten years, but often can be significantly more accurate than that with a proper setup. Sure, it’s slow, but we aren't looking to just make good knives – we're looking at every process to find what is the best way to do something. This same approach has been taken on every single step for every part we make.

First come, first served

When you sign up for our wait list, know that we are working around the clock to get one of our knives in your hand. We don’t take your excitement to have a TKC knife lightly and don’t want to waste your time by signing up and then have you wait years to get one.